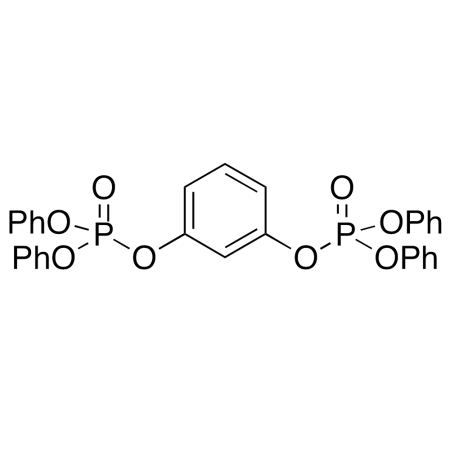

Resorcinol bis(diphenyl phosphate), commonly known as RDP, is a highly efficient, halogen-free, liquid phosphate ester flame retardant. This CAS number represents the well-defined monomeric structure, which is the foundational component of commercial RDP oligomer products. RDP is renowned for its excellent balance of flame retardancy, low volatility, good hydrolytic stability, and strong plasticizing effect, making it a premier choice for high-performance engineering plastics.

Flame Retardant Mechanism

RDP functions through a powerful combination of condensed-phase and gas-phase actions, with a dominant effect in the solid polymer.

• Condensed Phase Action (Primary Mechanism): Upon exposure to the high heat of a fire, RDP thermally degrades to form polyphosphoric acid. This acid acts as a potent catalyst on the polymer surface, promoting a dehydration and cross-linking reaction. This process rapidly converts the polymer into a stable, insulating layer of carbonaceous char. The high aromatic content of the RDP molecule contributes to the formation of a robust, glassy char that acts as a physical barrier, effectively:

1. Insulating the underlying polymer from heat.

2. Blocking the flow of oxygen to the polymer.

3. Trapping flammable volatiles in the solid phase, thus reducing the fuel available to the flame.

• Gas Phase Action (Secondary Mechanism): A smaller portion of the phosphorus-containing compounds volatilize, releasing phosphorus-based radicals () into the flame. These radicals are highly effective at scavenging and neutralizing the high-energy H• and OH• radicals that sustain the combustion chain reaction, thereby “quenching” the flame.

• Plasticizing Effect: As a liquid additive, RDP effectively plasticizes the polymer matrix. This is a significant processing benefit, as it improves the melt flow of engineering plastics like PC/ABS, allowing for easier molding of complex parts and often enhancing the final product’s impact strength.

Key Application Areas

RDP is the industry standard for achieving halogen-free flame retardancy in a variety of demanding applications.

• PC/ABS & PC/ASA Alloys: This is the largest and most critical application. RDP is used to achieve UL 94 V-0 ratings in housings for electronics such as laptops, monitors, printers, and power adapters, where both fire safety and good mechanical properties are essential.

• PPO/HIPS Alloys (mPPO): A primary flame retardant for modified Polyphenylene Oxide (PPO) alloys used in business machine enclosures, telecommunications equipment, and automotive components.

• Epoxy Resins: Used in the formulation of halogen-free laminates for advanced printed circuit boards (PCBs) and in electronic encapsulation compounds.

• Other Engineering Thermoplastics: Effective in various other resins, including certain grades of PBT and TPU, where its combination of flame retardancy and plasticization is advantageous.