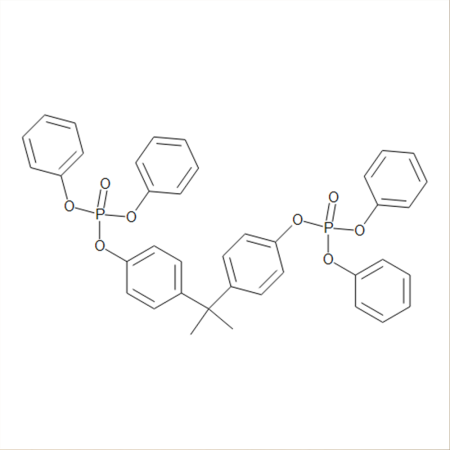

Bisphenol A bis(diphenyl phosphate), universally known as BDP, is a high-performance, halogen-free, viscous liquid phosphate ester flame retardant. It is characterized by its high phosphorus content, exceptional thermal stability, and very low volatility. BDP is a premier flame retardant for engineering plastics, particularly in applications that demand superior thermal performance and UL 94 V-0 ratings.

Flame Retardant Mechanism

BDP is an extremely effective condensed-phase flame retardant, meaning its primary action occurs within the solid polymer material during combustion.

- Condensed Phase Action (Primary Mechanism): When exposed to the intense heat of a fire, BDP thermally decomposes to generate polyphosphoric acid. This acid acts as a powerful catalyst on the polymer’s surface, promoting a rapid dehydration and cross-linking reaction. The high aromatic content from both the bisphenol A and diphenyl phosphate groups in the BDP molecule contributes to the formation of an exceptionally stable, dense, and glassy char layer. This insulating char acts as a robust physical barrier that:

- Shields the underlying polymer from external heat flux.

- Prevents oxygen from reaching the polymer surface.

- Traps flammable volatile compounds in the solid phase, drastically reducing the fuel supply to the flame.

- Superior Thermal Performance: As a high-molecular-weight oligomeric liquid, BDP exhibits extremely low volatility and outstanding thermal stability. This allows it to be processed at the high temperatures required for engineering plastics (e.g., >300°C) without significant degradation. This stability translates directly to the final part, resulting in a higher Heat Distortion Temperature (HDT) and better dimensional stability compared to many other liquid flame retardants.

- Gas Phase Action (Secondary Mechanism): While its primary action is in the condensed phase, a minor portion of the phosphorus-containing fragments can enter the gas phase. These fragments release phosphorus-based radicals (PO), which help to quench the flame by interrupting the free-radical chain reaction of combustion.

Key Application Areas

BDP’s unique combination of being a liquid (for ease of handling and dispersion) and providing high thermal performance makes it a top choice for demanding halogen-free applications.

- PC/ABS & PC/ASA Alloys: This is the primary market for BDP. It is used to achieve UL 94 V-0 ratings in housings for electronic devices (e.g., chargers, power tool casings, 5G infrastructure components) and durable automotive interior/exterior parts where excellent heat resistance (HDT) is essential.

- PPO/HIPS Alloys (mPPO): A key flame retardant for modified Polyphenylene Oxide (PPO) alloys used in enclosures for business machines, telecommunications equipment, and electrical components.

- Epoxy Resins & Laminates: Used in high-performance, halogen-free epoxy systems for electronic applications, including laminates for servers and data storage equipment.

- Thermoplastic Polyurethanes (TPU): Can be used in specialty TPU applications requiring high flame retardancy and thermal stability.