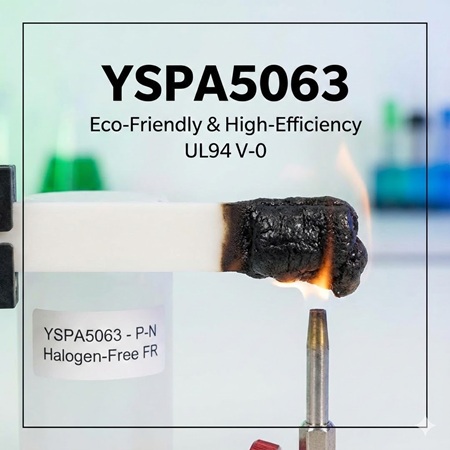

YSPA5063 series is an eco-friendly, high-efficiency Phosphorus-Nitrogen (P-N) based halogen-free flame retardant.

- Key Characteristics: Large particle size, high hydrophobicity, and non-migrating properties.

- Mechanism: It forms an intumescent char layer during combustion, which provides thermal insulation, oxygen barrier, and prevents flame spread.

- Advantages: Non-hydrolyzing, non-precipitating, excellent self-extinguishing char formation, and offers a better cost-performance ratio compared to Bromine-Antimony systems.

| Items | Specifications |

| Appearance | White powder/granule mixture |

| Particle Size (D50) μm | 10 |

| Moisture, % | <0.3 |

| Decomposition Temp (TGA 1%) °C | >350 |

Applications

- Target Material: Specifically designed for Polyamide (PA), suitable for both Glass Fiber (GF) reinforced PA and non-reinforced PA.

- Performance: The modified materials exhibit excellent physical and electrical properties.

- Typical Dosage: In PA + 30% Glass Fiber, a dosage of 15% YSPA5063 is typically sufficient to achieve UL94 V-0 (1.6mm).

- Appearance: Injection molded parts are white and do not turn grey.

- Processability: Good processing performance with no strip breakage and no foaming.

Processing Guidelines

- Drying: Nylon (PA) must be dried before processing; moisture content should be less than 0.1%.

- Temperature: Processing temperature should not exceed 350°C.

Packaging & Storage

- Package: Paper-plastic compound bag with inner plastic liner.

- Net Weight: 25 kg per bag.

- Storage: Store in a cool, dry place. Transport as general chemicals.

Important Notes

- Mixing: This product is a carrier-free masterbatch/powder. Low-speed mixing for 20–30 seconds is sufficient for uniform dispersion.

- Additives: Diffusion oil can be added appropriately to prevent layering.

- Warning: DO NOT use white mineral oil or other binders that are not heat-resistant.

- Mixing Speed: Do not use high-speed mixing to avoid stratification of the flame retardant and uneven feeding.